For the descendents of Richard Dearie and his son John Russell

Documents about the history of Malayan Collieries. 1934- January 1960.

Transcribed by Claire Grey unless otherwise stated.

July 12 1948

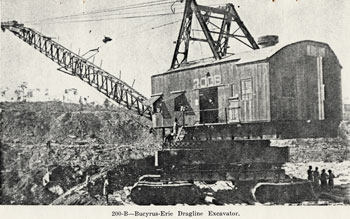

There was a communist attack on the colliery in July 1948 which together with the attack on an estate at Sungei Siput marked the beginning of the Emergency. The photos shows machinery which was wrecked by pushing it over the edge of the opencast workings.

The text below is from a booklet on the Collieries called MALAYAN COLLIERIES, LTD. (Incorporated in the Federation of Malaya) A DESCRIPTION OF THE PROPERTY, OPERATIONS AND SOCIAL ORGANISATION AT BATU ARANG COLLIERY.

Printed by Charles Grenier & Son, Ltd., Kuala Lumpur. It is dated October 1950. It is a photocopy of the original and some of the photographs are very poor reproductions. Where we have better quality copies of the same images these have been substituted.

The Company was founded in June 1913 by the late J. A. Russell, to whom a Malay brought the first sample of coal. Mr. Russell's vision and initiative were mainly instrumental in transforming the jungle site into a thriving industrial centre which, eventually, became the second most populous town in Selangor.

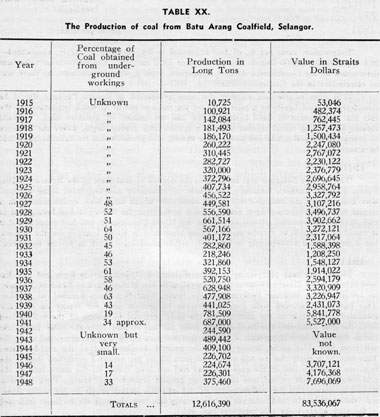

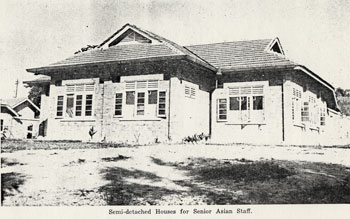

LOCATION: Batu Arang is roughly 30 miles by road from Kuala Lumpur in a north-westerly direction, in the state of Selangor. By rail the distance is 23 miles. The connection branches from the main line to Penang at Kuang. MALAYA'S ONLY COAL MINE: Other deposits of coal have been discovered in the Federation but none have proved extensive enough to be worked economically. AREA: The leases cover 9,000 acres, of which about 2,000 acres are occupied by surface plant, mine workings, housing etc. The coalfield is in the "form of an elongated basin 3 1/2 miles in length, and 3/4 mile in width with the major axis lying roughly north and south. POPULATION: The latest figures show a total of 9,479, comprising 6,799 Chinese, 2,540 Indians, 130 Malaysians and 50 Others. Immediately prior to the Emergency the population was 18,600 but a large number of these people were squatters living on the outskirts. STAFF: The Executive Staff consists of 23 Europeans, most of them married, with their wives and children on the property. A number of Asians assist the technical staff and there are over 200 clerical workers. LABOUR FORCE: This is made up of 1,228 Chinese, 1,092 Indians and 70 Malaysians—a total of 2,390. UNIONS: There are three in number, one for the labour force, one for the engineering technicians, and one for the clerical staff. The first was Communist-ridden and most of its Chinese officials joined the Terrorist movement when all-out violence was initiated in 1948. Chinese labourers have been slow to re-establish their section of the Union, a fact regretted by the Company, whose Officials had looked forward to friendly co-operation. COAL DEPOSITS: The coal is sub-bituminous in nature and has a lower heating value than that of most coals found in Britain. There are two seams which dip from the outcrop at about 14°. The average thickness of the upper seam near the surface is 36 ft., but lower down is much less. The other seam which occurs 200 ft. below also decreases in thickness, being about 22 ft. at the outcrop. The coal does not contain any natural inflammable gas and consequently the miners are able to use naked flame carbide lamps in the underground workings. In view of both seams outcropping at the surface it is possible to uncover and work some of the coal in the open until the proportion of overburden to be removed becomes too great to be economic. It is expected that the limiting ratio of overburden will be seven to one of clean coal. It is only possible to store the mined coal for any length of time under water, or by otherwise excluding the air, owing to its tendency to ignite by spontaneous combustion. It is useful therefore to be able to maintain a reserve of uncovered coal in the opencast. When the country was overrun by the Japanese this reserve amounted to about 450,000 tons. It was the first to be mined by the Japanese and under present conditions will take time to re-create. PRODUCTION: From 1915 when extraction began, until the present time, 13,250,000 tons have been produced. The highest output in any one year was 781,500 3 tons in 1940. During peak periods over 2,000 tons per day were supplied to the Malayan Railway, Power Stations, Dredges and other smaller consumers. The Japanese took 1,366,400 tons of the easiest won coal near the surface, thus causing heavy costs and considerable difficulties as regards subsequent operations. Production is now of the order of 1,400 tons per working day but it is hoped to increase this in the near future to satisfy the increasing demand. TRANSPORT: The Company's Railway system consists of about 7 miles of metre-gauge line, on which a dozen locomotives, with concomitant rolling stock, are employed. It connects with the Malayan Railway system, whose Batu Arang station, measured by the yardstick of tonnages handled both ways, ranks as one of the largest in Malaya. The Company also operates 18 miles of line running into its large forest concession to the north, from which is obtained the timber necessary for mining operations. This line also handles, by arrangement with the Malayan Railway, the traffic from the various rubber and palm-oil Estates in the same area. AIR-STRIP: This has been built since the Emergency, mainly for security reasons. SUBSIDIARIES: Brick and Tile Works: These were left, after the Japanese occupation, in a reasonably workable condition. Although bricks are used extensively in mining operations the kiln provides a large surplus for outside sale. -The average monthly production is 450,000 wirecut and pressed bricks of first class quality which is sufficient to cater for a large proportion of the requirements in the 'Federation. Heavy transport costs however make it difficult to compete with Chinese bricks, made nearer the building sites. - The Tile Works has been altered and improved since the War and an excellent roofing tile of the Marseille type is now proving popular on the market. Production is around 90,000 per month. Plywood Factory: This had been built up over some years into a large and efficient organisation providing Malaya's rubber and tea industries with a large proportion of their packing requirements at prices competitive with imported chests. Incidental products were pineapple cases and building panels for walls, ceilings, doors, etc. The large quantity of logs required to keep the peeling lathes busy was obtained partly from the Company's timber concession and partly from as far afield as Negri Sembilan. 1941 was a prosperous year and 1942 held promise of being still more successful. Large quantities of casein for glue making and other incidentals had been accumulated to meet a record demand. These stocks fell into the hands of the Japanese. The invaders made poor use of the plant and material and left the Factory in such a sorry state that, due to the difficulty of replacing machinery in a post war world and the necessity for giving priority to coal production, it was considered impracticable to proceed with rehabilitation of the Plant. With the cruder but effective means of packing rubber now in force (known as " bare-backed baling") it is doubtful whether plywood chests will ever again be employed for the purpose. ' Wood Distillation Plant: This produced methyl spirit, wood preservative and acetate of lime, with charcoal as a bye product. The Plant was left by the Japanese in the same dilapidated state as the Plywood Factory and for similar reasons any idea of its revival has been abandoned. JAPANESE OCCUPATION: With the advance of the Japanese late in 1941 the Company's stock of explosives and most of the mobile equipment, including tractors and bulldozers, were taken over by the Military. Principal items of plant were immobilized and the Power Station, sub-stations and main pumping units were destroyed to deny them to the enemy. Most of the European staff were members of one or other of the Defence services. Eventually twelve were interned and three lost their lives in attempting to escape. Of the Head Office staff of nine, eight were interned or became prisoners of war four of whom died— including the Chairman of Directors. When the British Military Administration took control late in 1945 the whole of the vital reserves of coal and much of that which could be easily extracted, had disappeared. It was therefore difficult to meet the needs of essential services. The worst feature was the neglected state of the plant and equipment and of all the housing of staff and labourers. The greater part of the water-born sewerage systems in the labourers' lines was out of action and no alternatives had been provided. New European staff began arriving before the end of 1945 and subsequently the Company took over full control of its property from the British Military Administration on July 1st, 1946. REHABILITATION: Government assisted by authorising a loan of $4,700,000/- to meet the Company's urgent needs for rehabilitation. Repayment of the Loan is spread over ten years commencing 1950. A substantial claim for the losses sustained has been made to -the War Damage Claims Commission but it is not yet known to what extent this claim will be met. Labour presented a problem from the start and though the Company's policy before the War had been to increase mechanisation, the urgency of this was now emphasized. It was decided to replace all tub and skip haulage, both on the surface and underground, with belt conveyors. Coal cutting machines and mechanical loaders were ordered on an experimental scale for the underground mines. Two more units have since been purchased. The pre-war excavating machines were reconditioned and put to work on removal of overburden and a fleet of large capacity dumping wagons for disposal of spoil, was purchased. The equipment for the Mines and Workshops which had been ordered in preparation, prior to the re-occupation, arrived during 1946/7. LABOUR TROUBLE AND THE EMERGENCY: Immediately following the reoccupation of Batu Arang when the Mine was being re-opened by. the British Military Administration and before any of the Company's staff arrived, the labour went on strike and the resulting stoppage of pumping operations caused disastrous loss of both underground and surface workings in addition to those already left semi-derelict by the Japanese. After some weeks, work was resumed but relations with the labour remained intermittently difficult and there was another strike of eight weeks duration early in 1947. The Government temporarily took control in order to maintain vital supplies of coal and some 1,200 Japanese surrendered personnel were moved in to assist in mining operations. The strikers' grievances were submitted to arbitration when their Representatives were given full opportunity to question the Company's Officials in public. The Arbitration award did not increase labourers' wages but the Company, by subsequent negotiation with the Union, increased the rates for piece work. Under the new rates, labourers were able to earn, if they worked with reasonable industry, as much as their counterparts in the U.K. The intransigent minority continued to agitate and caused sporadic dissension between Management and Labour. Batu Arang was the first big target at the beginning of the Bandit War. The possibility of this had been anticipated by the Management but, although all practicable precautionary measures were taken by the Company, it had not been found possible to obtain military protection and as a result the mine suffered a further serious set back in its progress towards recovery. Early on the morning of July 12th 1948, a large Communist force invaded the property. Five people were killed near the village. Extensive sabotage included damage to one dragline excavator, (driven over the edge of an opencast working) and to other machines by fire. Some of the earth-moving tournatrailers were immobilised by destruction of vital parts. This was a serious blow as there was little reserve of uncovered coal. The damage took months to repair, many parts having to be imported by air freight. The European staff, all of whom had been enrolled in the Auxiliary Police carried out allotted duties when the attack took place. Prior to the attack, the officials of the Chinese section of the Trade Union had fled into the jungle and are believed to have taken an active part in organising the Raid. Others who disappeared from the property were connected with Communist schools and are today amongst wanted bandits. A thorough screening resulted in over 200 people being arrested for collaboration with the terrorists. The Company instituted a system of registration whereby each employee was issued with an Identity Card bearing photograph and thumb print. This anticipated by some weeks the Government scheme of registration for the whole country. As a result of the Company registration it became possible to remove the large squatter population which had grown up during the preceding years on the outlying parts of the Property held under lease. This squatter group had been a stronghold of the subversive elements and its removal was essential to ensure proper control of the labour force. Notwithstanding the presence of military on the Property, there have been, since the raid other incidents of sabotage and a further six people have been murdered by terrorists. One newly-arrived member of the European staff was ambushed and killed while proceeding about his work and there have been other attempts without casualties. All the shops are now concentrated in the village area surrounded by a barbed wire fence, the only entrance being opposite the Police Station. In the interests of larger strategy the military have now been removed and protection entrusted to regular and special police. As an additional protection vital points liable to sabotage have been surrounded by heavy wire mesh fencing at Company's expense. Since the rooting out of Communist dissidents there have been no strikes or serious labour trouble of any kind. It is however, regretted by the 8 Company that the Chinese have not yet revived their section of the Trade Union. HOUSING: The re-conditioning of the dilapidated accommodation bequeathed by the Japanese has been a huge task. A number of the European bungalows were condemned as not worth repair and a considerable proportion of the workers' quarters has had to be rebuilt. New blocks of quarters for Asian Staff are models of their kind and are much appreciated by their occupants and admired by visitors. New permanent accommodation for labourers is still a major problem and the Company has recently embarked on a $500,000/- project which will take about three years to complete. SOCIAL AMENITIES: The village, situated in the centre of the property, surrounds the " padang " of the Sports Club where football, cricket and badminton are the most popular games. The Company owns a large number of shops of various types which are rented by shop keepers. There is also a Cinema where European, Indian and Chinese films are shown to packed houses. There are two Government run restaurants or canteens, which provide cheap but wholesome food and drink. A private bus company operates a service to and from Kuala Lumpur thrice daily. Since the Emergency the Chinese School has been entirely rebuilt by the Company at a cost of $40,000/-. It is large enough to accommodate 600 pupils but there are morning and afternoon sessions, thereby providing for 1,200 children. The Government grant is supplemented by a contribution of $12,000/- a year by the Company so that the children of Colliery workers can receive free education. The Tamil School building has recently been extended and now caters for 220 pupils. There also, education is free. An English school, previously run by a private individual for profit, has recently been taken over by the Company in order to improve the standard of education. An immediate increase in enrolment ensued and plans for necessary expansion are under consideration. Adult classes in English, to be held 3 evenings weekly, open to all comers of all races and either sex, began in September of this year. A newly formed Education Committee is busy organising scholarships available for promising pupils to enable them to further their studies outside Batu Arang. The Company provides a large Hospital and Dispensary, well equipped for indoor and outdoor treatment of all employees and their dependants free of charge. It is in charge of a visiting Medical Officer and a qualified resident staff can deal with most cases of sickness or accident. A modern ambulance is available for conveyance of patients, if necessary, to Kuala Lumpur hospitals. Health at Batu Arang is generally good with a remarkably low incidence of malaria. In spite of the Japanese neglect the anti-malaria squad has succeeded in recovering control over the breeding places of mosquitoes. In addition to the Sports Club previously mentioned the European Community is fortunate in possessing a well designed Club House, with facilities for billiards, table tennis and dancing. Two excellent hard tennis courts are attached. The prewar Provident Fund for European employees built up by equal contributions from employer and employee of 5% of salary, has since been increased to 10% contributions. A similar Fund is now in existence for Asian Staff whose services, prior to the initiation of the Fund, are covered by additional gratuities payable on retirement.

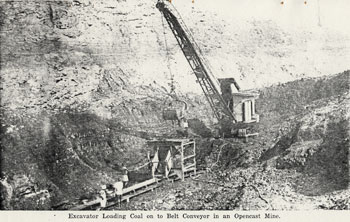

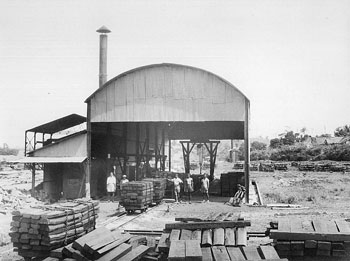

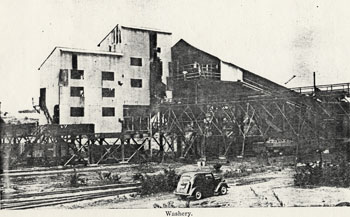

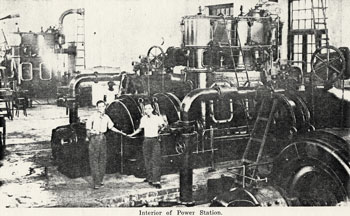

MINING OPERATIONS AND PLANT: OPENCAST: In the early part of the post war period, while development plans were being finalised, several opencast sites were worked in various parts of the property. In 1948 the policy of concentrating all opencast operations on one site was formulated and the deep stripping programme at Opencast No. 1 began. This scheme entails the removal of more than six 10 million cubic yards of overburden, for the recovery of about one million tons of coal. The stripping of overburden which will reach the limit for the lower seam at a depth of 200 feet from the surface, is done by four large dragline excavators. The largest of these is the 200-B Bucyrus-Erie machine which has a 137 ½ feet boom and a 4 ½ cubic yard bucket. This is the machine which was damaged by terrorists in 1948 and which has been rebuilt at the Company's Workshops. Coal is won from the face by means of 1 ¼ cubic yard draglines or shovels and loaded into hoppers from which belt conveyors transport the coal to the railway wagons. A considerable proportion of the coal as mined contains fireclay and other impurities which necessitate its passing through the coal washing plant before despatch to consumers. 350,000 tons of coal have already been won from Opencast No. 1 and it is expected that the remaining coal on this site will last about three years. The equipment will then be moved to a new site near the Washery, where there is a considerable reserve of workable coal in the upper and thicker seam. UNDERGROUND MINES: In the past, underground mines have been worked at a number of places both in the upper and lower seams. Previously mines were driven in the coal seam exposed at the bottom of opencast workings but the later method is to drive the entries from surface level to facilitate drainage. The largest of the pre-war mines, known as the East Mine, was unfortunately completely lost by fire in 1939. The entrances to this mine in the lower seam were situated in the area which is now being worked as Opencast No. 1. It had been partially reopened by 1941 but all this work was destroyed as a result of the Japanese occupation. It is hoped to win some of the coal beyond the limits of the old workings from West Mine, the development of which had been commenced immediately after the loss of East Mine but which also suffered severely during the occupation. The post-war policy has been to develop two underground mines, one in the lower seam, the West Mine 11 and the other in the upper seam known as No. 2 Mine. A third mine is now being developed, but only on a small scale, with the object of prospecting and proving the lower seam to the south of the old East Mine workings. The West Mine: This has had several setbacks, the last being a serious fire in April 1950 which resulted in the workings having to be partly flooded, a great deal of equipment being lost—both as a result of the fire and also from the effect of the water. The mine is now being recovered but is not expected to produce any appreciable output of coal until 1951. No. 2 Mine: This Mine is designed to produce 1,000 tons per day and while still in only the development stage is producing over 500 tons in two eight hour shifts. The third shift is devoted mainly to maintenance and repair work. The liability of the coal to spontaneous combustion determines, to a large extent, the method of working and very great precautions have to be taken to prevent local heatings developing into extensive fires. The main entries to the mine are driven on the full dip of the seam and pairs of levels are driven to left or right, thereby opening up a considerable area of coal for subsequent extraction. All main roads are now supported by steel arch girders as under present day conditions these are considered more satisfactory than timbers to control the weak overlying shale. The transport of coal from the working face is now mostly by scraper chain and belt conveyors and in several headings coal cutting machines are working. One mechanical loading machine is at work and is popular with the workmen who operate it. Finding sufficient labour of the right type for underground work is a major problem and only by the training of men to make proper use of mechanisation methods can it be expected to get the required output from the underground mines. Under conditions where the majority of the coal is loaded at the face by hand, two tons per man per eight hour shift is not being achieved. With skilled operation of suitable machines it is hoped to obtain double this figure, 12 Coal Washery and Screens: Before the Japanese occupation the Company had two Washeries combined with screening plant. After the re-occupation one was found to be completely derelict and useless. The other one now operating is South of the railway station and deals with all the dirty coal produced from the opencast and underground mines. The Run-of-Mine coal is delivered to an unloading shed by rail in air dump cars of 12 cubic yard capacity and hand operated side dump cars of 5 cubic yard capacity. The coal is tipped down a sloping bench with controlled feed on to a horizontal plate conveyor. This delivers to an inclined belt conveyor which carries the coal to the screens. Here it passes over jiggers where it is graded into Large and Smalls. The Large goes to the picking belts where stone and other impurities are taken out by hand and from there it is delivered into wagons. The Smalls travel by incline belt to the main washery bunker, over-size pieces passing through a crusher. The cleaning of the coal is done by the wet process on the " Baum " principle of pulsation by air. The coal passes from the main bunker to the washer box, where the pulsation causes the dirt to be freed from the coal. The coal is carried by the water on to and over de-watering screens and thence to the wagon. The stone and dirt sinks and is collected from the washer box by control gates and a worm conveyor. From here, by elevator and belt conveyor, it is carried away and dumped into an old opencast pit. The water used in the process goes to a settling pond and is then re-circulated. The capacity of the Washery is 60 tons of raw coal per hour. POWER SUPPLY: Practically the whole of. the plant on the Property is operated by electricity and prior to the Japanese occupation sufficient power was generated in the Company's own station. The whole of this equipment was destroyed at the time of the 1941 evacuation and that left by the Japanese was found in a derelict condition. At Rawang, eleven miles away, Rawang Tin Fields Limited owned a power station in workable 13 condition. With that Company's ready and helpful collaboration the Colliery was able to draw current for all its power needs from 1945 until recently. Since the reoccupation the Company has installed 3 new generating sets developing a total of 1,500 K.W. It is now drawing the balance of its requirements from the Central Electricity Board's power station at Bungsar, Kuala Lumpur. This Board's long-term planning includes new stations and a grid system for the entire country. It is intended eventually to draw the whole of the Collieries' power requirements (estimated at up to 4,000 K.W.) from this source, the Batu Arang plant being retained as an emergency stand by. Continuity of supply is vital to the security of the Mines because of the heavy pumping load and the tropical deluges which occur from time to time. At Batu Arang, power is generated and distributed at 3,300 Volts, The supply from the Central Electricity Board is brought in by overhead lines at 33,000 Volts and stepped down through transformers to 3,300 Volts when it is in parallel with the local supply. Distribution to the various parts of the property is carried by ring mains to sub-stations where the power is further stepped down to medium pressure—440 Volts for general purposes or 220 Volts for lighting. WATER SUPPLY: The power and domestic water supply in Batu Arang is catered for by an impounding reservoir with a capacity of 85 million gallons situated in the Rantau Panjang Forest Reserve. The water is pumped and piped from there to various points such as Power House, Workshops, locomotive stands and tanks for domestic reticulation. A portion of this supply is at present treated by the aid of precipitation tanks, pressure niters and chemicals. It is hoped in the future similarly to treat all water required for domestic purposes. WORKSHOPS: In its Workshops, the Company caters for the repair of plant and machinery and, in a great many instances, the manufacture and renewal of equipment. The buildings comprise the following: Machine 14 Shop and Assembly Bay, Angle and Blacksmiths Shop, Locomotive Sheds, Wagon Repair Shops, Foundry and Pattern Shops, Carpenters Shop, Electric Welding Shop, Lorry Repair Department and Tractor and Tournatrailer Repair Sheds. To facilitate heavy repairs and overhauls to the large excavators and the unloading of lorries and trucks, a " Portal" travelling crane of 10 tons lifting capacity has been erected in the Workshops compound. STORES: The Stores Department comprises an extensive yard in which are four large brick buildings, the whole area being surrounded by a wire fence. Since supplies of machinery and plant and the necessary spare parts come from England or America and delivery is slow and erratic, it is necessary to keep large stocks. Nos. 1 and 2 Stores buildings contain light and medium weight stores and No. 3 holds cement, lime, paints and oils. No. 4 Store, where there is an overhead travelling crane, holds all heavy machinery, wire rope and cable. The Stores buildings and yard are served by road and rail. SAWMILL AND IMPREGNATION PLANT: The Sawmill was found to be in an extremely poor condition at the re-occupation and due to the priority given to the Mines, renovation is not yet complete. Previously, the main functions were carried out by steam but the plant is now completely electrified. The large seasoning shed was dismantled and removed by the Japanese but is being reconstituted. Further modifications and improvements will be carried out as time and pressure of other work permit. Logs arrive at the mill by road and rail, and are off-loaded at the log yard. From there they are hauled by winch to the head saw platform and, as required, are rolled onto the head saw carriage. This machine which is of the circular type, produces the baulks and planks, etc. as required. From here the timber passes on rollers to two ripping saws which reduce it to the final scantlings required. A pendulum cross cut saw squares ends and cuts to length. Much of the local timber lacks durability when exposed to sun and rain, therefore the Company has installed a simple impregnation plant of the open tank boiling type. By this method it is hoped to prolong the life of sleepers which otherwise might have a relatively short one. The operation is as follows: Sleepers and other timber to be impregnated are stacked for six months in the seasoning yard. They are then formed into clamps of 28 with spaces between each sleeper, and loaded into a steel tank which is steam heated and then water cooled. The tanks are filled with a mixture of creosote and fuel oil—50% of each oil. For four hours they are cooked by the steam heat. After this, they are cooled down quickly by the water coils and left soaking in the tank for a total of 24 hours. When they are taken out the surplus oil is drained off and they are ready for use. RESCUE AND FIRE STATION: In order to deal with any surface fire, the Station is equipped with a modern trailer fire pump. A system of hydrants provides sufficient water at a number of points on the Property. Important buildings are also equipped with fire extinguishers. The Rescue Station is well equipped with " Proto" Mine Rescue apparatus and the necessary auxiliaries. Three teams of trained underground men, although not employed full time on this work, can be assembled at short notice. A continuous system of inspection is maintained underground to guard against outbreaks of fire.

THIS BOOKLET has been published for the information of those associated with or interested in the Company and it is hoped that it will be found of interest. October 1950.